When the desire to be Made in France is in the genes of the project, discover how Alexia Desporte, CEO of the startup Popotte Duck, makes this challenge the strength of her project. Because producing in France can be a source of many opportunities, discover how to overcome the cost barrier with Made in Asia.

Popotte Duck : choosing to make in France today

Presentation of the client

Popotte Duck was born with the goal that as many people as possible eat as well as possible.

This cooking companion puts its intelligence at the disposal of its users to establish a schedule of healthy and balanced/varied recipes and takes care of making regular and personalised shopping lists.

The project and its challenges

Rtone has had the privilege of supporting the startup through various stages and technical choices since the beginning of the project. The desire to create a product made in France served as a guiding principle for the teams.

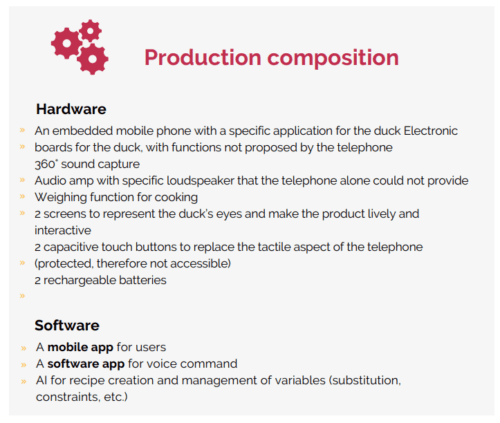

Numerous challenges influenced the technical choices, particularly on the hardware side.

To achieve a design-oriented, user-friendly, and intelligent companion, several essential features were developed. For example:

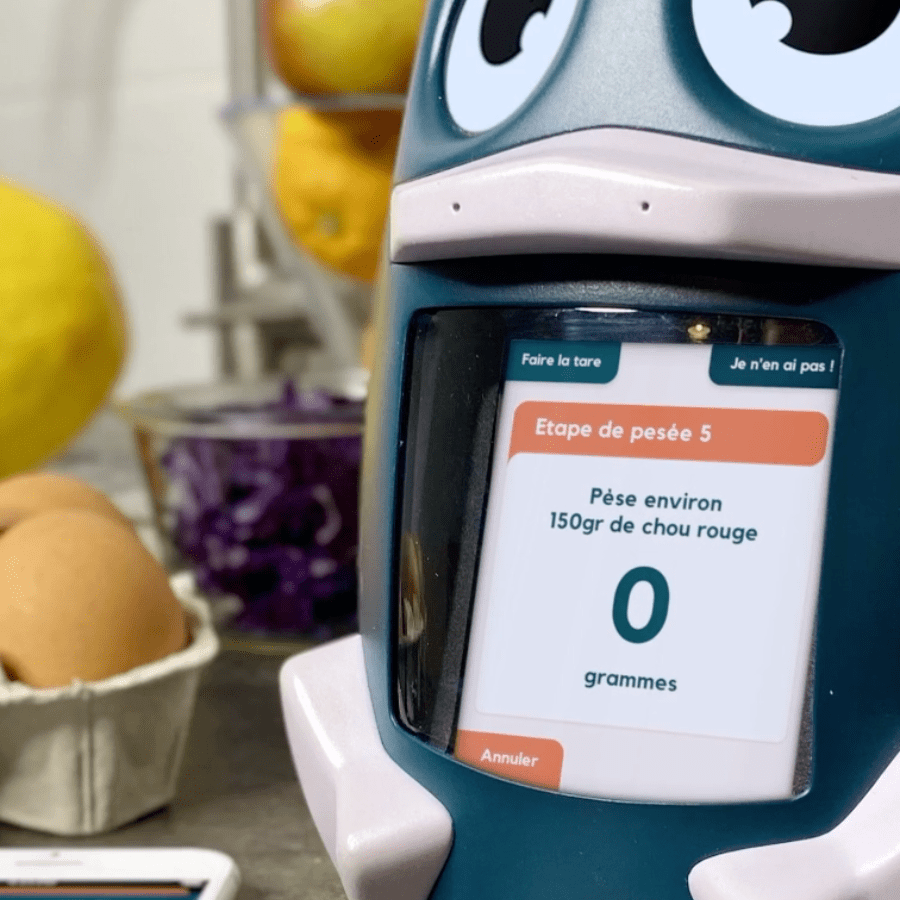

- A weighing function for culinary tasks

- Two screens to represent the duck’s eyes, making the product interactive and lively

- Two capacitive touch buttons

- Two rechargeable batteries

- An entire sound capture system

Not to mention the software and embedded intelligence, featuring AI for recipe creation and variable management.

Made in France production

The decision to produce the product in France was made very early on. Producing in France often comes with challenges. The Chinese manufacturing ecosystem, especially for designing a physical product with hardware, is often seen as an easier solution.

However, thanks to our end-to-end industrialization approach, anticipated from the product design phases, we were able to support the startup in this decision to pursue French production.

Why overcome the barriers of “Made in France”?

1. To avoid supply and transport issues and ensure uninterrupted production for the project

2. For ethical and responsible reasons, such as creating jobs in France and limiting environmental impact by avoiding air freight from Asia

3. Because we can! All the necessary expertise exists in France. Although much has been outsourced, it is still possible to assemble a French production ecosystem.

4. To avoid misunderstandings and linguistic or cultural barriers

The challenges of “Made in France”

Time

With fewer manufacturers in France than in Asia, it can take longer to develop the exact components needed.

Cost and lack of competition

Production volumes are much smaller than in Asia. Consequently, costs can be a limiting factor. Additionally, with fewer players in the market, it’s harder to leverage competition to secure lower prices.

Shortages of certain components

Due to the outsourcing of production, certain components are no longer available in France.

Turning “Made in France” into an opportunity

Choosing an off-the-shelf product

For the duck’s functionality, the decision was made to use a smartphone, which conveniently combined the screen and the equivalent of a custom-designed electronic board. This was the most cost-effective option. Unnecessary features were disabled, and the smartphone was specifically adapted for this project to run only the dedicated duck application. By making this choice, production costs and time-to-market were minimized thanks to an existing product (eliminating the need for extensive research and development).

Understanding and perfectly meeting user needs

Through field tests and focus groups, the goal was to create a product that consumers would love, avoiding the need for costly redesigns during production. These workshops also helped the startup realize that a physical product was essential, as a simple app among many others would not suffice.

Getting the right support

Rtone’s teams connected the startup with trusted French partners for the various skills needed to design the product. All subcontractors were based in France.

Adapting the business model

Creating a physical product often means relying on sales for revenue (costly when Made in France). Unless the data you gather is invaluable to other players. This is the strategy chosen by Popotte Duck: analyzing tomorrow’s food trends to make them available to manufacturers and distributors.

Our case studies

Discover the problems of your peers, the solutions provided by our teams and above all the results.

Let's talk about your project!

You have a product development project? From design to industrialization, through serial life and maintenance, we are here to support you at each stage of your project. Feel free to submit your most ambitious projects to us.

We look forward to hearing from you!