by Benjamin Vincent, Embedded Software Developer

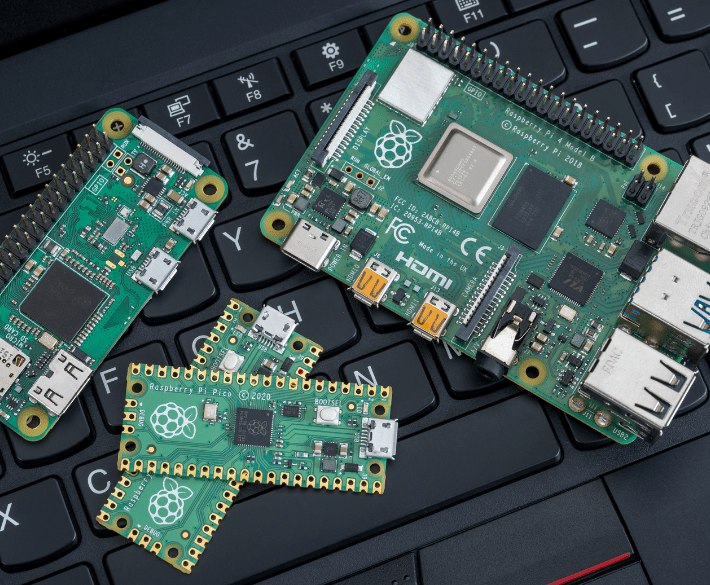

With more than 25 million units sold, Raspberry Pi is the most famous “nanocomputer”. This open development platform, which allows prototypes to be programmed for around €35, is supported by a strong community of enthusiasts. However, since its launch in 2012, the Raspberry Pi has been mainly used by the educational world and a public of “hobbyists”.

What are the limitations of Raspberry Pi boards? Are there solutions adapted to the industrial sector? Here are some answers according to Rtone, offering you an alternative Raspberry Pi for the industrial sector.

The limits of Raspberry Pi for the industrial sector

The Raspberry Pi was originally developed to make computer programming accessible to a wide audience.

A lack of durability

In this ‘general public’ context, the availability of the boards is therefore of little importance. For example, the Raspberry Pi 3 Model A+ and B+, which started production in 2018, are guaranteed until January 2023.

These models are thus incompatible with the launch of large-scale industrial production, because :

- An industrial project requires at least 2 years of studies before launching a product, which leaves only 3 years of production at most;

- There is no guarantee of the number of cards available.

Poor temperature management

The Raspberry Pi’s processors are robust, but they have the disadvantage of getting hot and are not optimised for heat dissipation. This is especially problematic as temperatures are often higher in industrial environments.

This phenomenon is amplified with the Raspberry Pi model 4, which has seen its performance greatly increased. Its heat dissipation is limited, so much so that software patches had to be developed to reduce its power consumption and thus reduce thermal losses.

This software optimisation does not eliminate the need to add fans to limit these heat losses.

A corruptible medium: the SD card

On a Raspberry Pi, the operating system (Linux) and applications are stored on SD cards. However, SD cards are not very well suited to the industrial context, because flash memory is easily corrupted. The slightest power cut during the writing cycle can cause errors and render the system inoperative.

In addition, the SD medium – in its engineering – is not a format that is convincing in the industrial sector. Indeed :

- Vibratory stresses add further risk, as the connections between the reader and the card can be interrupted

- The fact that the SD card can be easily removed adds a second risk.

The lack of RTC in the Raspberry Pi

PLCs need to be able to carry out time-scheduled tasks, so they need a clock. For security reasons, these automatons may not be connected to the Internet; they are equipped with an electronic block called RTC (Real Time Clock).

Through the use of a low-frequency oscillator with a low temporal drift, this block allows the time to be determined relatively precisely (in general, the drift is estimated at a few seconds per year). It also ensures its retention thanks to its very low energy consumption – guaranteed by a battery offering several years of autonomy.

The Raspberry Pi does not have a battery, so they have to make do with a time reading of relative precision, a reading that drifts by several tens of minutes per year. Furthermore, if the Raspberry Pi is switched off, the accuracy of the time is no longer guaranteed. As a matter of fact, when it is restarted, the microcomputer will start again at the time it was switched off.

It is possible to use an NTP (Network Time Protocol) service which allows a server to be interrogated to synchronise the local time, but this requires a specific infrastructure in an industrial environment (local or remote NTP server via the Internet).

Potential disruptions and security flaws

Finally, the Raspberry Pi is initially designed to favour the development of personal or school projects. Therefore, they incorporate many connectors and inputs/outputs in order to multiply the possibilities.

When a project is in the “prototype” phase, this feature is interesting. However, in an industrial context, two problems arise:

- The number of security holes is proportional to the number of inputs/outputs; these must therefore be limited;

- The free connectors of the Raspberry Pi are all antennas capable of picking up electromagnetic signals. However, in an industrial context, where the number of machines is high, there are numerous electromagnetic disturbances. One consequence of this phenomenon can be a system malfunction due to the chaotic behaviour of the electronics.

The Raspberry Pi Compute Module 3: a solution designed for the industrial sector

As mentioned, the potential for industrial use of the Raspberry Pi has been limited until now. Nevertheless, the Raspberry Pi Foundation and its co-founder Eben Upton were aware of its limitations.

In 2017, they launched a new version of the Raspberry Pi specifically for industrial use: Raspberry Pi Compute Module 3

Features of the Compute Module 3

This new industrial-specific version is a Raspberry Pi module that is plugged into a motherboard. The main advantages of the Raspberry Pi Compute Module 3 over the consumer versions are

- More flexibility and modularity;

- A processor at least 10 times more powerful than the previous version;

- 2 times more RAM;

- Integrated eMMC memory. Optional SD card;

- SODIMM format which allows the module to be integrated with a motherboard or a PLC;

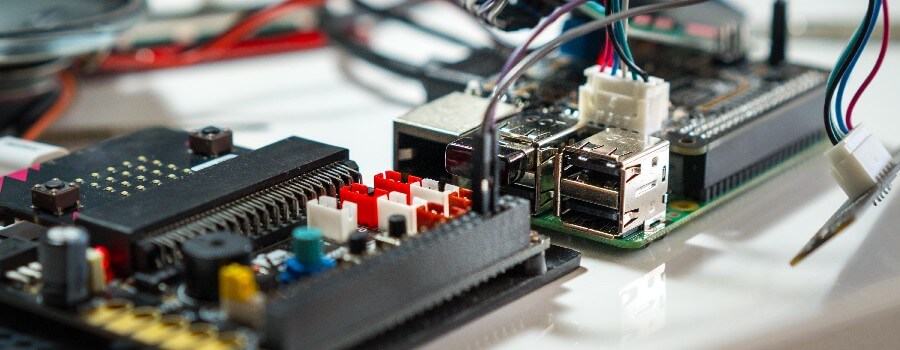

Compatible circuits and motherboards

The modules are compatible with boards equipped with a SODIMM port designed for this purpose. These boards can take many forms and be :

- Developed specifically by an industrial company for a particular application;

- Generic boards. Many players are designing architectures capable of integrating these Raspberry Pi Compute Module 3s and filling in some of the gaps that may remain.

There are potentially many options:

- RTC electronic block, for time management;

- Temperature management system;

- More robust power supplies;

- Electromagnetic shielding;

- Integration of communication protocols such as Modbus;

- The addition of standard industrial ports such as RS232/485;

Revolution Pi: a modular industrial PC

Industrialists wishing to integrate Raspberry Pi modules directly can turn to the modular industrial PCs of the “Revolution Pi” range, certified to EN 61131-2 and IEC 61131-2.

These slim DIN-rail format machines include everything you need to implement your IIoT projects and are available until 2026.

With new products that seem to fill the gaps in the Raspberry Pi, its arrival on the industrial market is now a reality.

Contact an expert