For many IoT projects, it is a race against time. The challenge is to come up with the best solution in the shortest possible time. In other words, you have to be as productive as possible. From the idea to

For many IoT projects, it is a race against time. The challenge is to come up with the best solution in the shortest possible time. In other words, you have to be as productive as possible. From the idea to

For many IoT projects, it is a race against time. The challenge is to come up with the best solution in the shortest possible time. In other words, you have to be as productive as possible.

From the idea to the production of your object, there is a decisive step, the prototyping.

Prototyping is the moment when your object becomes tangible.

At what point do we talk about a product prototype or an industrial prototype? How do you approach this manufacturing phase of your connected object?

That’s what we’ll look at in this article.

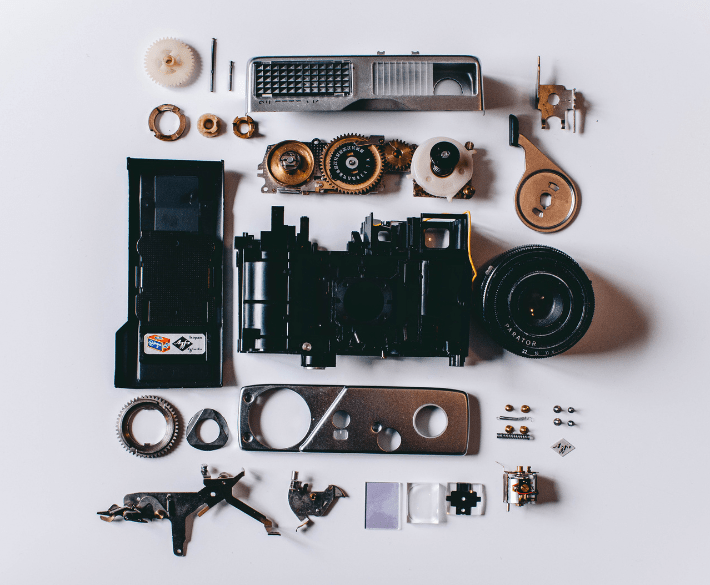

In a nutshell, prototyping takes the idea of the project from the “virtual” object to the physical object. It involves crystallising the technical choices and components to obtain a functional model.

However, it is not a model. We will see this later.

The first stages of design and development of a connected object include all the phases between the idea and the validation of the product.

You will also carry out some tests relating to functionality and aesthetics.

Before producing a prototype, you will probably go through the following steps:

Why go through these stages?

The more you break down the phases that precede the industrialisation of your product, the more you ensure that you have a reliable, functional product that meets the expectations of future users.

This also allows you to optimise the schedule and the budget of your overall project.

We will come back to this point in more detail later in this article.

Download the guide from poc to prototype

Your prototypes may be either functional or industrial.

Functional prototypes allow you to visualise the technical aspects of the product: dimensions, materials, design, ergonomics, functionality, etc. This allows you to have an initial assessment of the user experience.

Industrial prototypes prepare the object for industrialisation. They go further than functional prototypes and integrate the constraints linked to the manufacturing process.

In this article, and in the case of the manufacture of connected objects, we will focus on industrial prototypes.

Functional prototypes are integrated into the previously described mockup, PoC and MVP phases.

Industrial prototyping puts you in manufacturing conditions. You understand the cost and volume constraints. You also come to test the manufacturing processes, i.e. the way each part and each material is designed.

With your industrial partner, you will come and talk about machining, moulding solutions, sheet metal work, injections, etc.

The question to be answered is: “how to make the product?

Also, thanks to industrial prototyping, your manufacturing partner will have a clear vision of the manufacturing process of your object.

In short, the prototype allows you to :

The final step in the design of your connected object is its commercialisation.

The prototyping phase also prepares the way for the marketing of your product.

How do you do this?

First of all, thanks to your future users. The prototype is the first opportunity to get in touch with them in a tangible way. If you present your prototypes to a group of beta testers, you will get customer feedback and validate your solution.

In addition to information about the performance of your solution, you will gather valuable information about compliance and security.

Finally, it also allows you to prepare the packaging aspects of your product.

To design a prototype that is as close as possible to your future product (and thus avoid numerous iterations), we advise you to think in terms of the final product.

In concrete terms, what does this mean?

You design and develop your prototype by thinking about the desired features, the main functionalities and the uses of your future users.

> Go further and read the article on the added value of a connected object.

You are certainly eager to have your finished product in your hands.

However, designing an innovative product involves a long design and development phase, with multiple technologies and skills.

Before you start creating prototypes, take the time to validate your PoC and MVP.

Why?

First of all, these preliminary stages will already allow you to validate several points: technological feasibility, ergonomic choices, and the main functionalities.

Furthermore, creating a prototype requires you to take the step towards manufacturing processes and therefore to invest in the means of producing the various components. However, if you have already validated the functions, materials and technological choices in the preliminary phases, you will avoid iterations. As a result, you will reduce the time and costs of this prototyping phase.

After prototyping, you will prepare the deployment of your product. This will involve small or large-scale production of your object.

Before going to market (the final deployment), your prototypes can be used for initial pilot deployments. Making these “test” products available allows you to evaluate customer perceptions and also detect any problems or errors that need to be corrected.

This will allow you to limit the number of iterations in the production phase and thus reduce the duration and cost of this phase.

> Watch the video on the deployment of a connected object

As we have seen, the prototyping stage prepares the industrialisation of your product. You integrate the industrial constraints.

However, this industrialisation stage involves new challenges and a new time/budget dimension for your project. It is common for project leaders to be confronted with unforeseen events during this phase which considerably delays production and therefore affects the time to market of their solution.

The best advice we can give you here is to be well supported in this prototyping and industrialisation stage.

More specifically, we advise you to get in touch with your industrial partners as soon as possible and not just contact a prototypist.

We talk more about this in this video:

> Read the article on the stages of industrialisation of a connected object

Let’s finish with one of the “red thread” subjects in your project: the budget.

You are certainly looking to make the best budgetary choice at each stage. However, let’s not beat about the bush: the cheapest prototypist will not necessarily be the most efficient and the most qualitative.

Remember, the objective of prototyping is to prepare for the next stage of industrialisation and therefore to integrate production constraints.

The challenge is not so much to choose the cheapest option at this stage as to optimise the overall budget.

In other words, the prototyping stage should be considered as an investment to guarantee a product that :

> Read the article on the ROI of your connected object.

This is the approach we take in supporting innovative projects, from design to industrialisation. A global vision to secure the perimeters for the carriers and the users.

Do you have an innovative product design project?

Our design office can assist you in the design, development and industrialisation phases of your product.

Contact us to discuss your project

Un peu de lecture

Des articles, des podcasts, des webinars… et surtout des conseils pratiques ! En bref, une collection de ressources pour mener à bien votre projet.