The industrialisation of your product is like the hidden part of the iceberg. Yet it is just as important as the development phase. In order not to miss this crucial phase, a phase that will allow you to launch your

The industrialisation of your product is like the hidden part of the iceberg. Yet it is just as important as the development phase. In order not to miss this crucial phase, a phase that will allow you to launch your

The industrialisation of your product is like the hidden part of the iceberg.

Yet it is just as important as the development phase.

In order not to miss this crucial phase, a phase that will allow you to launch your product and put it on the market, you must anticipate it from the start of the project.

But not only that. Industrialisation is not an additional stage that you start after the development phase. It should be seen as a common thread that runs throughout the progress of the project, in parallel with the development and progress of the product.

But why? And how, in fact?

What are the impacts if you don’t prepare the subject early enough?

In this article, we’re going to talk to you about the Rtone approach, which is to integrate this phase from the start of the project in order to respect all the cost price, volume, quality and deadline indicators that you have set yourself.

Let’s go, we’re taking you on board!

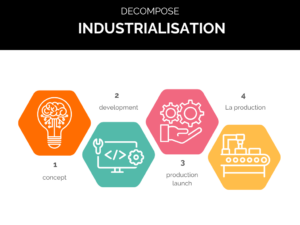

This is how the development of a product can be broken down:

There is a tendency to think that industrialisation starts with the production launch.

In absolute terms, this is not totally wrong. But it all depends on the objectives you have set yourself:

If these objectives have been defined and quantified, the industrialisation phase should not take you away from them.

Our approach is to build industrialisation throughout these 4 stages. To develop it progressively in parallel with these 4 major milestones.

This is how integrating industrialisation from the start-up phase and in parallel with your project will help you to meet your cost, quality and deadline objectives.

At the start, you have an idea, which has become your product. You have established a business plan to make it profitable.

The objective of the “Proof Of Concept” is to gather the technological building blocks to demonstrate the feasibility of product development. This phase must result in a functional demonstrator that is consistent with the desired design.

At this stage, nothing is yet created or designed. We simply know the product’s functionalities, the expected volumes and the targeted cost price.

Various stages will enable us to match your product idea with its industrialisable, feasible and manufacturable reality.

This is how it is organised.

This is where the industrial risks are first analysed.

Is the product manufacturable? For the given volume? In large series?

Can the manufacturing process be industrialised? That is to say, can the operations be replicated (manually or otherwise)?

Then we will look at the cost price. With a little experience, we can give an idea of the cost price of the product, based on its functionality.

This order of magnitude will be sufficiently precise to redirect the project, if necessary.

For example, a connected product that was estimated to cost €10, but which, after the first estimates, turns out to be closer to €40, will raise real questions for the project leader. Experience has shown us that this allows them to reposition their project and to save precious time by not having to wait for the famous production phase to become aware of the discrepancy.

Indeed, the product’s functionalities will indicate which production investments are to be planned, such as budgets for equipment and production launch.

These costs are quite substantial. They differ, of course, according to the project and the complexity of the product, but they can easily reach hundreds of thousands of euros. This stage enables the project leader to be aware of the importance of these costs and possibly the need to incorporate them into the planned fundraising.

Here, the team’s knowledge and experience will be used to identify the main risks that could slow down or block the project at a given time.

Are there supply risks on certain materials or components? Certain destinations? Design risks?

In this phase, we create the production schedule. The project leader will be able to adjust his time to market according to what has been planned and will thus be able to propose a more realistic availability date for the product to its future users.

The definition of indicators for the industrial project is becoming clearer. It will be possible to define :

All of these stages are decisive for launching the project as it is or not. They allow you to review your volume and fundraising ambitions, which are often underestimated when it comes to industrialisation.

Here is a video that explains Rtone’s approach, as described in this article:

The development stage integrates all the functionalities. It allows the prototype to be developed and industrialised.

During the development phase, the team of experts in industrialisation will be a little less present and will have a limited workload after having intervened during the concept phase to define the KPIs.

It will mainly be general development monitoring to ensure that the indicators are met.

In doing so, the team can assist the client in their choice of technologies.

Its role is to help the client in its strategic decisions and to alert the client to any drift in the industrialisation process that could have an impact on:

However, generally speaking, the team does not intervene on the technical part, the performance of the product or its functionality.

In Agile project management, monitoring will be reinforced because the scope changes more often and it is necessary to be able to act early enough to anticipate the impacts on the industrialisation phase.

Some very specific and complex missions can start during this phase to optimise the time of the next phase of the production launch.

For example, the integration of new partners, or of certain uncontrolled processes, can take more time and can sometimes even force a review of the design to be able to integrate the production constraints into the design.

These projects generally involve complex products and new processes.

Production launch means putting a developed product into production.

This stage defines the tools and the industrial layout necessary for the manufacture and assembly of products in series.

It involves preparing and assembling everything to enable production.

Starting with sourcing partners.

To find the right partner or partners, it will be a question of identifying them, carrying out studies, increasing the number of exchanges, visiting them and comparing them

This phase also makes it possible to identify the processes and industrial constraints of each partner if several are involved.

This phase can last several months.

This is the stage where the conductor brings together all his musicians.

Each partner must be able to work together and their processes and constraints must be combined to produce the final score of the production.

During this phase, the focus will also be on defining the integration process when it is not the manufacturer who is in charge.

This may be the case when plastic injection moulding is used, for example.

This is therefore where the production files will be built.

We will also try to provide for a specific workflow if there are several partners: to set up intermediate controls, at the entry and exit of each production to ensure that everything is in conformity and that everything is correctly integrated.

The idea here is to ensure that the pre-production runs are in line with the planned production schedules.

The aim is to leave the project once production has stabilised. What exactly does that mean?

It is once we have :

The production phase uses the industrial tool and will require dealing with field feedback and improvements to the product and the production line.

This phase can be managed by the client or by our teams.

Here are the different objectives:

The aim here is to ensure that the adopted manufacturing and dispatch rate respects the delivery target set.

One of the most crucial parts of your business will be monitoring non-conformities, whether on electronic boards or on finished products.

What actions are put in place to monitor productivity?

Taking into account possible scrap rates, are we still able to keep up with the pace?

What plan can be put in place to reduce production time and defects?

The aim is to stabilise production and improve the quality level.

To dig a little deeper into the subject of industrialisation and, in particular, the time it can take, we recommend this video:

There may be a final stage to this industrialisation phase which may be a subject for reflection upstream: monitoring the quality of the product over time.

It is necessary to be able to manage non-conformities and find an appropriate solution when they occur.

How can we manage the equivalence or obsolescence of components?

And possibly plan for the end of life of your product, if this has been defined beforehand.

You can only benefit from taking the subject of industrialisation as a common thread throughout the development of your product.

It helps you to: have a better vision of your global costs and your cost price, to draw up a fairer schedule and to optimise your time to market, but also to guarantee the quality that you initially set for your product.

You now have all the keys in hand to successfully industrialise your intelligent product!

Un peu de lecture

Des articles, des podcasts, des webinars… et surtout des conseils pratiques ! En bref, une collection de ressources pour mener à bien votre projet.