You have industrialised your product. You have reached the end of this phase and you have been able to see your product go to market. Congratulations! But now, what happens to your product? The idea is not to let it

You have industrialised your product. You have reached the end of this phase and you have been able to see your product go to market. Congratulations! But now, what happens to your product? The idea is not to let it

You have industrialised your product. You have reached the end of this phase and you have been able to see your product go to market. Congratulations!

But now, what happens to your product?

The idea is not to let it live without monitoring and observation.

What happens if a component becomes obsolete? What happens if you find that you are receiving more and more products in after-sales service?

These are all points to keep an eye on once production has stabilised and the product has been put on the market.

In this article, we explain what the different topics of serial life are and how to deal with them.

Let’s get started!

Serial life is what happens once the production has stabilised.

It can be managed by the service provider who accompanies the project leader on the subject of industrialisation but it can also be managed by the project leader themself.

Industrialisation is a decisive phase for the marketing of your product. It should be anticipated and integrated as early as possible. Why should you do this?

To allow you to anticipate the schedule of your product and integrate all the costs and investments necessary for the completion of your project.

Moreover, at Rtone, we apply industrialisation as a common thread. This means that it is broken down and that it occurs at each phase of product development.

> To explore this topic in more detail, you can read this article.

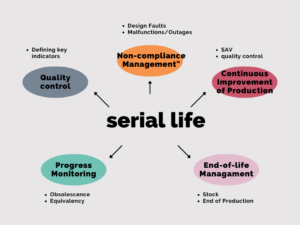

Serial life is the process of ensuring that :

The serial life intervenes mainly on the mechanical, hardware and software parts of the product.

Here are the different aspects of serial life:

Serial life begins with the establishment of indicators. In order to be able to identify and avoid certain… the indicators will enable alerts to be raised if necessary.

Non-conformities can occur in two cases:

It is therefore necessary to be able to manage and correct these failures. In most cases, this means :

Continuous improvement in production requires incorporating customer feedback.

This can be through setting up an after-sales service that needs to be trained and can train other members to join the team. In short, the more documented, the better!

Quality monitoring will also enable you to identify design or manufacturing problems.

Throughout the production process, various changes may occur. It is necessary to be able to prepare for these changes:

At some point, a decision will have to be made as to when to stop manufacturing the product.

We can advise the client on this strategy. There can be several options:

The Rtone teams accompanied Lunii on the electronic and software study of the serial life of their product Ma Fabrique à Histoires, i.e. they proposed the redesign and the associated software evolutions, according to the various optimisations to be carried out. Management and production of the serial life were operated by their French EMS BMS Circuits.

Rtone and Lunii worked on 3 axes of the serial life:

With a view to limiting the failure rate and increasing the reliability of the product, certain actions have been taken by the teams:

In order to reduce costs:

Managing the current shortage of components

To deal with the current shortage of components, solutions had to be found:

The Rtone teams managed the upstream phases up to the functional test bench, the end of the manufacturing of the boards.

BMS Circuits also managed the replacement of identical components in order to continue production in several cases.

My Story Factory by Lunii

The same principles also apply to the Cloud. We will talk about maintenance of the product or platform.

Whether the product is stabilised or continues to evolve, there is always a development team that knows the product and will follow up on bugs and updates.

And even if test cycles have been previously completed, there may still be :

As a general rule, a Cloud service is constantly evolving.

It is often the development team that works on the evolutions because they are the ones that know the product best and will be able to correct it quickly.

For software that does not evolve, however, there comes a time when bugs become increasingly rare and eventually disappear.

This is a procedure that describes all the functionalities and situations to be tested each time the software is put into production. Even the most basic ones. So as not to forget any of them:

Because each addition of functionalities leads to recurrent bug loops.

First, there is a development phase, during which we look for bugs and correct them as we go along, in the following sprints.

Then there is an initial production phase. Non-expert users will start using the platform and often their work depends on it. Two things are essential:

Then comes the natural cycle of evolution of the service.

Different versions are used to follow a development process that integrates updates, bug fixes and new features while trying to limit risks.

The “dev” version is one that will evolve every day, with all the additions made by developers. This version is only tested by a small specific group: the project manager at the client’s, for example.

Then we build a staging version. This is a pre-production version, which is very similar to the production version. We will use real data as much as possible, with the same performance, under the same conditions.

Then it is finally the production version that is used. We are talking about a fixed version, a versioned version. We know which version of the source code is deployed.

The subject of serial life allows you to accompany your product or service throughout its life. It is what will enable you to ensure the level of quality of your product that you have set yourself.

Integrating this subject as early as possible will enable you to anticipate and manage obsolescence, time extensions, problems in after-sales service, etc.

And to foresee its end of life.

In short, whether it is a product or a service, you have the keys to continue to satisfy your customers and to apprehend the challenges that you will face.

To discover the story of Lovebox's industrialisation, download the free guide

Un peu de lecture

Des articles, des podcasts, des webinars… et surtout des conseils pratiques ! En bref, une collection de ressources pour mener à bien votre projet.